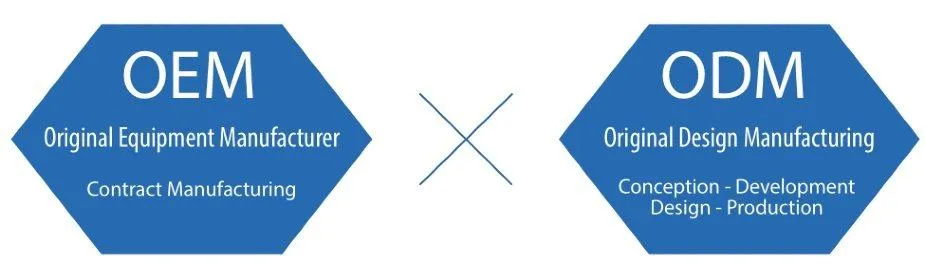

You might come across terms like ODM and OEM manufacturing when researching factories to carry out your company’s production. What are the key differences between the two types of manufacturers that you should pay attention to? In this article, we will give a detailed explanation of ODM and OEM to help you gain a full understanding of them and invest your money and time in the right one, whichever industry you are working in.

Definition of ODM and OEM

What is Original Design Manufacturing? Examples of ODM?

ODM stands for Original Design Manufacturer, which refers to businesses that develop the designs of the goods, manufacture them and sell them to other companies who want to rebrand the products as their own. The general idea is that you are taking advantage of suppliers who can already manufacture the goods of your interest.

What is Original Equipment Manufacturing? Examples of OEM?

The abbreviation OEM is short for Original Equipment Manufacturer. An OEM manufacturer does not come up with its own designs; instead, it manufactures the goods and components based on the designs and specifications (colors, materials, functions, etc.) provided by the outsourcing company. Buyers then sell the finished products under their brand name and own the trademarks to these products.

Differences between ODM and OEM in Production

Types of products

ODM

With ODM service, brands are buying a pre-designed and pre-produced product that will be sold under the name of the buyer companies. You can require to make negligible alterations to the goods or differentiate yourself from the pack by designing a unique packaging; however, it’s highly likely that there are similar or identical competing products on the market.

OEM

Since OEM products are based on the buyer’s particular prototypes, they are perfectly customizable. Sometimes, brands may outsource the production of components or separate parts of a good, instead of a complete product, to a OEM manufacturer. These parts will later be transported to other locations to be assembled and labelled before being sold by the buyer under a trademark. Because these are specific pieces of a single product, the buyer often orders a high volume to minimize the costs incurred.

Main industries

ODM

There are several industries that benefit significantly from ODM services:

- Textile and clothing

- Fast-moving consumer goods (beauty products and foods)

- Consumer electronics (phone cases, chargers, etc.)

- Medicine

OEM

Many different industries are making the most out of outsourcing their mass production to OEM firms, such as:

- Automotive sector

- Complex electronics (software and hardware)

- Textile and clothing

These industries often cover multinational corporations that have large-scale order requirements, complex design specifications and constant innovations.

Pros and cons of ODM and OEM

ODM

Advantages

- Low development cost

The greatest plus point of opting for ODM over OEM is that there’s no need to spend financial resources on Research and Development and designing a product from scratch. By leaving most of the technical aspects to the ODM suppliers, which wield a depth of knowledge of the manufacturing side, you can allocate a larger body of your resources in market research, brand development and product marketing.

- Time- efficient

For OEM manufacturing, you may need a lot of time to come up with a product design, consult a supplier and arrange a custom production line. By opting for an ODM solution, you can save time in the setting up period. Moreover, marketing and selling pre-produced, finished products are much easier and quicker compared to a component product.

Disadvantages

- No product exclusivity

An important disadvantage to note is because ODMs have large runs of items to sell in smaller lots and buyers don’t make much customization, brands cannot have access to unique products and thus, they must face harsh rivalry from other businesses competing in the same space. This requires you to either lower your profit margins as competition goes on, or pay third party consulting firms to help you choose an exclusive ODM.

- Limited to certain products

Additionally, ODM manufacturing is only useful for certain types of products, especially those in industries mentioned above. If your brand wishes to obtain a heterogeneous or new product, it is doubtful that you will find an ODM firm that provides your desired model. In a situation like this, it’s better to seek information from an OEM firm.

OEM

Advantages

- Opportunities for new products

Although OEM solutions are often chosen by multinational corporations with large order requirements, they are also gaining popularity among small and medium-sized enterprises. If your company is a start-up which is adept at designing and branding but lacking knowledge and capabilities in manufacturing, OEM services are ideal for you. Because the brand already has the original idea and processes like testing and branding ready to go, it only requires a manufacturer that offers skilled labor and supply chains at reduced costs to help meet product demand. Besides, unlike ODM, complete customization is available at OEM factories.

Moreover, your company will have the exclusivity to sell the products since all the trademarks and intellectual property rights related to the designs, plans and products belong to you.

- Cost-effective

When entering into an agreement with an OEM manufacturing firm, you benefit from receiving cost-effective products. The production of high quality and highly specialized goods can be costly if you do not have the necessary setup or expertise; therefore, making use of professional external production and exclusive technology proves to be a much more economical decision. The more products are manufactured, the lower the cost will be. In turn, you will have the time and money resources to invest in core functions at your business. Also, it’s important to note that brands with unique goods are capable of charging competitive prices and becoming market leaders in their product categories.

Disadvantages

- High order quantity

The biggest drawback of working with OEMs is that in order to make profits out of the reduced costs, a large majority of suppliers only allow a high order quantity, normally from 3000 pcs. Hence, if you are not confident in selling enough outputs to procure their services, you should not capitalize on OEM firms.

- Few qualified OEM manufacturers

Since a lot of detailed specifications go into the production of the OEM products, perfection is the number one criterium in the manufacturing procedure. Although all brands expect first-rate quality in reception of their goods, few OEM suppliers in the markets can provide services at or above par. Moreover, the finding of OEMs can be considered a burden for brands because OEMs take a lot of time to establish and assemble the necessary setup and technologies for products.

These are the basic differences between the ODM and OEM models. If you are looking for a knitted fabric and garment manufacturer for either pre-produced or newly-designed products, Thygesen Textile Vietnamwould be your perfect partner. By choosing Thygesen Textile Vietnam, you will receive premium custom clothing manufacturing services. We focus on perfecting our own capability of providing a super supportive OEM/ODM manufacturing service to share more value with our customers by saving their cost, time and effort spent on manufacturing high-quality products. Contact us now to experience top-notch service and bring your ideas to life.